Systems & Facilities

Serving an energy demand equivalent to that of 42,000 homes, the University of Iowa (UI) utilities system includes two power plants, a water treatment plant, a chilled water plant (primarily for air conditioning), and an extensive distribution system. All of these facilities and their equipment are centrally managed and maintained by the University of Iowa Energy Collaborative.

Main Campus Power Plant

Augmenting two utility-owned substations on the main campus, the UI Power Plant provides energy security to all the main campus buildings. The plant has the capacity to generate 39.6 MW of electricity, as well as steam for heating, cooling, and sterilization.

Built for resilience, the main UI power plant houses multiple redundant generation systems. These include four natural gas electric reciprocating engine generators, three steam turbine generators, three natural gas boilers, and two solid-fuel boilers. The latter are increasingly using biomass to replace coal as a fuel input, in keeping with the University’s Path to Zero Coal by 2025 goal.

Oakdale Plant

Located on the UI Research Park campus, the Oakdale Utility Power Plant is a trigeneration plant with four natural gas boilers, two natural gas reciprocating engine generators, three chillers, and two satellite chillers. The plant produces electricity, heat, and cooling for over a dozen buildings including the State Hygienic Lab, the UIHC Integrated Services Center, and the Environmental Management Facility. The Oakdale Plant also houses two natural gas reciprocating engine generators and a diesel generator that switch on and provide electricity to the campus’ research buildings in the event of a power outage.

Water Treatment Plant

The University of Iowa is one of the few universities that operate their own water treatment plants. The plant purifies and distributes water across the UI main campus, to academic facilities, dormitories, hospitals, and clinics. Originally built in the early 1960’s, the plant has been repeatedly expanded and upgraded to meet increasing demand and to address environmental concerns.

In addition to providing a cost-effective source of water for the campus, the plant also serves as an important teaching facility for future engineers and water treatment specialists. Students work alongside the full-time plant staff members to complete routine maintenance tasks and receive support in obtaining their Grade I and II Water Treatment licenses.

Chilled Water Plant

The University of Iowa primarily uses chilled water to provide cooling for 90 buildings across the main campus. UI’s first chilled water plant opened in 1970. Today, the chilled water system has expanded to include four plants and three satellite chillers.

With the advent of increasingly volatile warm-weather seasons, the University of Iowa Energy Collaborative is working to upgrade the chilled water systems so that they can continue to provide necessary cooling to all the buildings, while reducing energy consumption and operating costs.

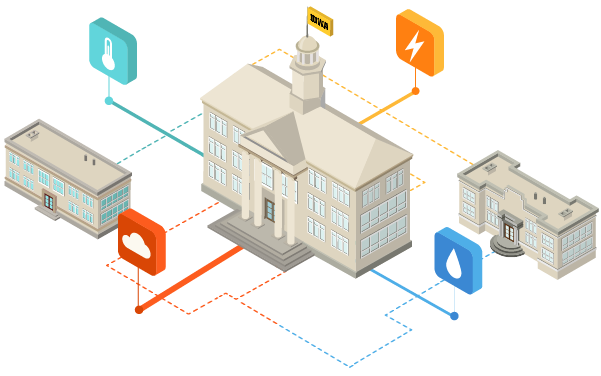

Energy Control Systems

UI’s Energy Control Center (ECC) serves as a centralized location for the monitoring, analysis, and forecasting of energy consumption and supply across the university’s campuses. Meters on campus buildings transmit data on steam, electricity, and chilled water production and usage to the ECC in real time.

ECC staff use this data to generate internal billing and to monitor the university’s progress toward its environmental sustainability and operational efficiency goals. For example, the ECC’s careful oversight of campus electricity usage enabled UI to find significant sources of energy savings in the decade from 2010 to 2020. Even though the university added several new buildings, including a new children’s hospital, it did not increase its overall energy usage, thanks to the savings it achieved in other areas.

Distribution Systems

UI’s utility distribution comprises all the conduits and mechanisms for conveying electricity, water, steam, air, and sewage into, across, and out of the campus. It also includes all the meters and controls for the electrical and mechanical distribution systems.

The Iowa Energy Collaborative is managing this extensive system, which includes some 42 miles of 13.8kV cable, connecting more than 250 building substation transformers and switches. The Energy Collaborative also maintains tunnels, vaults, and direct-buried piping for steam and condensate, chilled water and domestic water piping and hydrants, compressed air, as well as storm and sanitary sewer collection systems. Distribution system functions run over a secure fiber optic network, which is separate from the corporate and university IT networks.